What an amazing bespoke Packing System we have to show to you today, integrating an infeed gravity roller system to a fully equipped packing system, with bench-mounted scales & Andon light system.

Table dimensions: 1800mm x 1000mm x 975mm

Frame material: Welded mild steel square hollow section finished in Epoxy powder coated painted / Blue RAL 5010

Bench worktop: Galvanised top complete with 300mm long 3 lane gravity roller conveyor fitted to back of top

Storage: Upper MDF storage, bottom MDF shelf, pull out MDF shelves, steel lockable drawer, steel bin hoop, pull out shelf for a bin with boxes for void fill

Andon Light: 3 x light (red, yellow & green) andon kit complete with signal box - fully wired

IT Equipment: Monitor and keyboard bracket, PC mount, integrated bench scales

Our packing bench product was designed specifically for our clients bespoke needs, if you have any questions or want to request a similar design, please contact us for a free quote.

For all enquiries please contact us

Phone: 01482 363445

Email: sales@spaceguard.co.uk

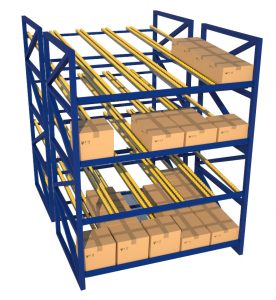

This design is a workbench designed to improve packing operations, especially in high-volume environments. This type of packing bench integrates a gravity roller conveyor at the infeed, allowing for the smooth transfer of items to the packing area.

How an Infeed Gravity Roller Packing Bench can Improve your Process:

Boost Efficiency:

By integrating a gravity roller, you can significantly reduce the need for manual lifting, which, in turn, allows items to move smoothly to the packing area. As a result, this continuous flow minimizes downtime and ultimately speeds up the entire process.

Minimize Physical Strain:

Moreover, the bench actively reduces physical strain on employees by offering ergonomic benefits. This not only enhances comfort but also lowers the risk of workplace injuries, especially repetitive strain injuries (RSI).

Streamline Workflow:

Additionally, integrating an infeed conveyor into the packing bench creates a more organized and logical workflow. With products quickly positioned for packing, the process becomes more efficient, thereby eliminating potential bottlenecks.

Enhance Versatility:

Furthermore, these stations are highly versatile and customizable to meet specific needs. Whether you're handling small items or bulky products, the table can easily adapt with various roller sizes and styles to fit your operations perfectly.

Achieve Cost-Effectiveness:

In addition, this type of packing bench boosts productivity while reducing labor costs, making it a cost-effective solution for optimizing your packing process. The initial investment is quickly offset by long-term savings through durability and efficiency gains.

Ensure Durability:

Finally, constructed from robust, heavy-duty materials, these benches are designed to withstand the demands of daily industrial use. This ensures not only long-term reliability but also longevity in the most demanding environments.