Carton Live Storage Rack units are ideal for picking and packing areas along with organising parts for assembly areas.

Carton Live Storage Racks are manufactured from the ground up for new systems or can be integrated into existing installations.

They are commonly used in small packing warehouses as standalone solutions to improve picking & packing efficiency, or within giant distribution centres to help online retailers to make most of the available warehouse space.

All carton storage and flow racks are manufactured to order to suit your size and space requirements.

Need Help? Contact us

- Experienced UK Manufacturer

- All products delivered fully assembled & ready to use

- Wide range of options & accessories

- Helpful sales & support teams

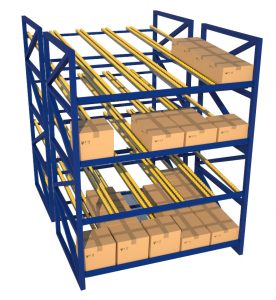

How carton live storage systems work

Carton storage racks are ideal for picking, packing and product assembly areas. They are loaded from one end and unloaded from the other ensuring the operative has a supply of goods at all times.

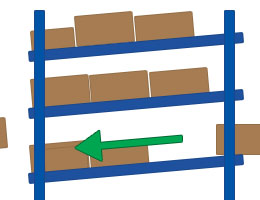

The concept behind these systems relies on using different types of gravity tracks positioned within a racking system at a slight decline to allow various products to move freely within the system increasing warehouse efficiency

The boxes are positioned in individual lines depending on the size of your product. The front box is positioned to allow packers easy access to the contents and for removal. Removing the front box allows gravity to take over and pushes the rest of the line towards the front and allows more rear product loading.

Live storage Rack Variations

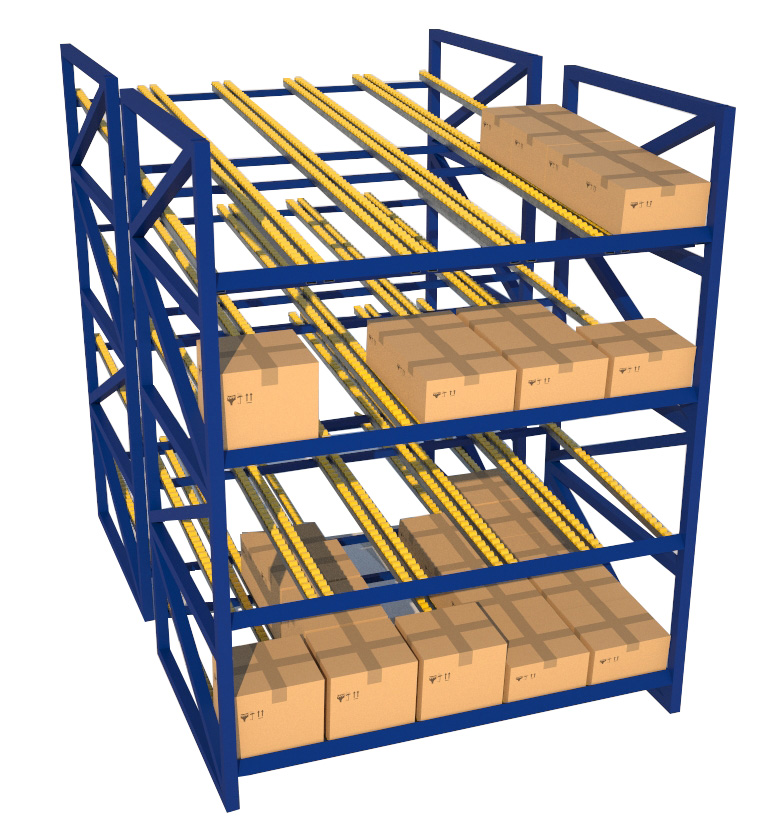

Our flow rack systems will utilize one of the 3 gravity products below.

Skate Wheel

Light duty conveyor system which is suitable for larger products, large gaps between individual skate rollers keep the costs down making this an economical solution

Conveyor Rollers

This is the heaviest duty version available, it is suitable for larger products and containers as well as products with uneven surfaces. These allow many different shapes of products to flow due to no gaps providing the rollers sit at a tight enough pitch

Micro Tracks

The most commonly used roller track for these systems, they are ideal for small containers, boxes and totes. Usually they are installed in paired tracks at a pitch the width of the product to allow the smoothest carton flow.

We manufacture fully bespoke carton live storage solutions

No Carton live storage system is the same, so we don’t offer a one-fit carton flow storage racks solution,

we take the time to learn about your business and products and take into consideration other factors when designing your bespoke racking system such as

- The shape/size and weight of the product

- The speed of throughput

- Whether products are handled manually or by machinery

- The dimensions of the building including the heights of ceilings and available floor space

We can build specific widths & heights, add as many shelves as required and track widths or pitches to suit your product.

Our flow rack systems are usually manufactured in two variants depending on the product weight and dimensions.

Normally our shelves are set at one specific angle throughout to give the optimal decline for your products to move, however we can also utilize knuckled shelves which can be used to increase packers' visibility and access to the front package.

Please contact our team with your requirements to receive a free quotation.